Aug 07 , 2025

The production of sintered NdFeB magnets begins with rare earth elements, particularly neodymium, praseodymium, and dysprosium, which are combined with iron and boron to form the raw material foundation of one of the world's most powerful permanent magnets. The balance of these elements is critical because even a minor change in composition can directly affect magnetic strength, thermal resistance, and long-term stability. Companies such as Ketian Magnet have mastered this delicate process through years of technological advancement, ensuring that each batch of raw material is carefully refined and tailored for high-performance applications.

Once the rare earth materials are prepared, they are melted and cast into alloys, which are then crushed into fine powders. This powder preparation stage is vital to controlling particle size, uniformity, and purity. At Ketian Magnet, advanced equipment ensures that the powder is optimized for maximum performance. The next step is magnetic alignment, where the fine powders are placed in a magnetic field before pressing. This alignment process orients the magnetic domains in a specific direction, greatly enhancing the final magnet's strength and performance. The precision of this stage sets the foundation for the superior quality that Ketian Magnet’s products are known for worldwide.

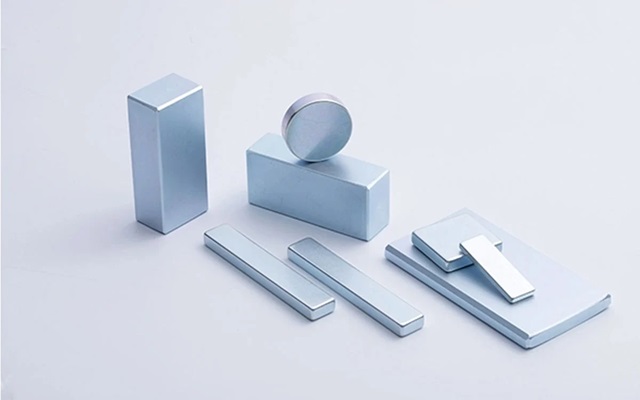

After pressing and alignment, the compacted powder is sintered at extremely high temperatures. This sintering stage causes the particles to fuse together, forming a dense and solid magnet structure. During this process, careful control of temperature and atmosphere is crucial to achieving desired properties such as coercivity and maximum energy product. Heat treatment follows sintering, further enhancing the magnet's stability and resistance to demagnetization. At Ketian Magnet, modern production facilities and strict quality control ensure that every sintered NdFeB magnet achieves consistent high performance, suitable for demanding applications in electric vehicles, wind turbines, and medical devices.

Feature | Sintered NdFeB Magnets | Bonded NdFeB Magnets |

Magnetic Strength | Very high, ideal for heavy-duty applications | Moderate, suitable for lightweight devices |

Thermal Resistance | Excellent, can withstand higher temperatures | Limited, less stable in extreme conditions |

Density and Durability | High density with robust mechanical strength | Lower density, more prone to wear |

Manufacturing Complexity | Complex, involves sintering and heat treatment | Simpler process using polymer bonding |

Application Range | Widely used in EVs, wind turbines, and industry | Often applied in electronics and sensors |

This comparison highlights why sintered NdFeB magnets, despite their more complex production process, are preferred for high-demand sectors requiring superior strength and durability. NdFeB magnet manufacturer such as Ketian Magnet specializes in this precision manufacturing, ensuring that the magnets meet the rigorous requirements of global industries.

The applications of sintered NdFeB magnets continue to expand as industries seek higher efficiency and more compact designs. In electric vehicles, they serve as the core components of traction motors, providing both high torque and efficiency. In renewable energy, particularly wind turbines, they play a vital role in generating power with minimal energy loss. Medical equipment such as MRI machines also rely on these magnets for their strong and stable magnetic fields.

As global industries evolve toward electrification and sustainable solutions, Ketian Magnet is poised to lead in developing next-generation sintered NdFeB magnets that combine higher performance with eco-friendly production practices. With its expertise, global reach, and commitment to innovation, Ketian Magnet continues to transform rare earth resources into high-performance magnets that drive progress across multiple sectors.

Founded in 2001 in Ningbo, Ketian Magnet has emerged as a leading Chinese high-tech enterprise dedicated to the research, development, and production of high-performance NdFeB magnets. With certifications including ISO9001, ISO14001, IATF16949, ISO45001, and ISO27001, the company has built a reputation for excellence, innovation, and trust. Its product range covers multiple series, from 56M, 55H, 55SH, 54UH, 52EH to 45AH, ensuring versatile solutions for diverse industries.

Affiliated with Ningbo Jintian Copper (Group) Co., Ltd., Ketian Magnet benefits from the strong industrial foundation and global presence of a group enterprise with more than 46 subsidiaries and operations in over 100 countries. Leveraging advanced technology, strategic partnerships with universities, and a highly skilled workforce, Ketian Magnet has established itself as a supplier of world-class bulk neodymium magnets. Today, its products are widely used in electric vehicles, automobiles, wind power, medical devices, and various industrial applications, trusted by customers across Europe, America, and Asia.